Individually configurable

Assemble your machine exactly to your requirements.

The perfect entry-level model – the F2 at a glance.

10” touchscreen with 3D graphics support.

3.5 min. heating time.

That's why the F 2 is the perfect entry-level model

Assemble your machine exactly to your requirements.

We guarantee that your production runs and that the calculation is correct.

A Hebrock is always an investment in the future.

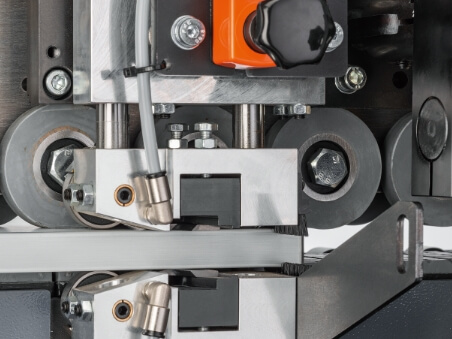

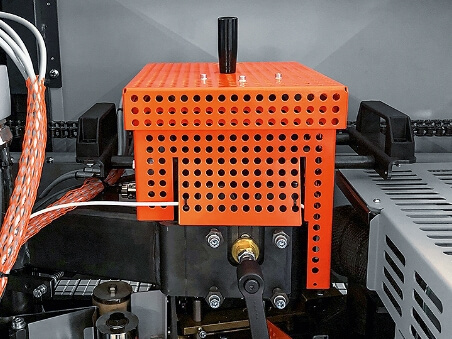

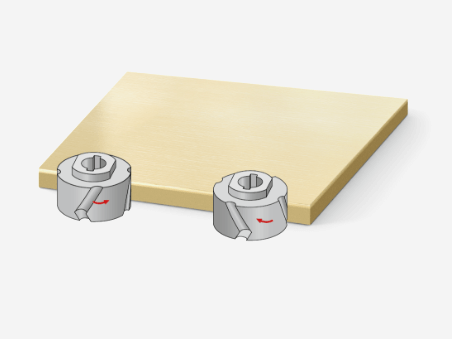

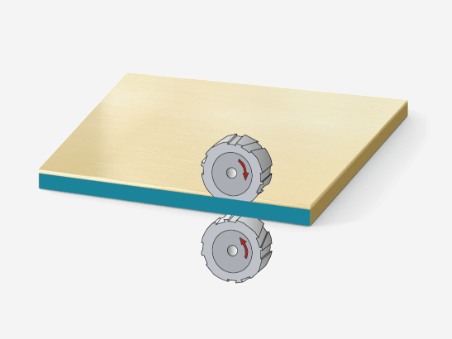

The 3.3 m long F 2 will save you both space and money. And it also has the specifications you require to process perfect edges right from the start – diamond-tipped cutters guarantee superbly prepared workpieces for edging. The specifications include pre-milling aggregate (up to 2 mm cutting depth), the top-side fast-heating glue pot, trim saw and combi-cutter. The F 2 can also be optionally fitted with a surface scraper.

Altendorf edge banding machines are suitable for almost every type of wood. Whether solid wood, chipboard, blockboard, MDF or multiplex - you can always rely on precise and clean edge processing (including finishing).

These HPL sheets are available in a variety of dimensions, thicknesses and surface finishes. And to be processed efficiently and flexibly with Hebrock edge banding machines. Our machines are suitable for different material dimensions. So pay attention to the respective technical profiles.

Edge banding on plastics, for example on PP sandwich panels, is an important part of the craft. With Hebock edge banding machines, you also rely on productivity and flexibility during processing. And always offer your customers first-class quality.

chop saw

jointing machine

Milling unit

Further equipment:

| Max. edge thickness | 3 mm |

| Min./max. workpiece thickness | 8 – 50 mm |

| Min. Min. workpiece length | ca. 160 mm |

| Feed speed | Ø about 5.9 kW |

| Electrical connection | 400 V – 3 Ph – 50 Hz |

| Machine’s dimensions | about 3,350×1,300×1,400 mm (LxWxH) |

| Work table height | about 900 mm |

| Weight | about 620 kg |

| Exhaust connection | Ø 1 x 140 mm |

Surface scraper

As with our machines, we also place the highest demands on our service.