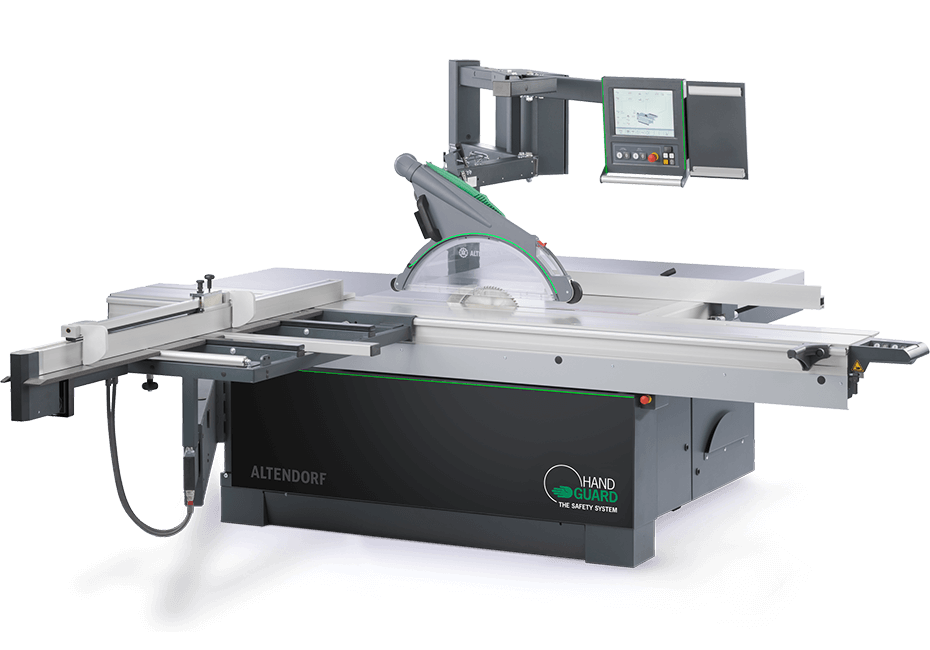

Whenever groups were formed at the trade fair stand of the new Altendorf Group, it happened regularly during the demonstration of the latest developments on an Altendorf sliding table saw. The professional audience from all over the world was amazed when an employee of the Altendorf Group’s development team guided their hand towards the saw blade at normal feed speed – and no injury occurred. The saw blade simply disappeared in a split second. It was a 400 mm saw blade that worked at approx. 5000 rpm In addition, the saw blade is braked to a standstill. This safety system also works with larger saw blades.

Karl-Friedrich Schröder, Head of Development at the Altendorf Group, explained the drive behind the groundbreaking development of “ASA” to around 120 international trading partners at the dealer evening: “We were not satisfied that existing systems, like the well-known “saw stop”, always only start after the accident has happened and at the same time destroy parts of the machine. Our goal was to start earlier. First and foremost, we wanted to avoid accidents and life-threatening injuries, i.e. to protect the operator. To do so, we have to recognise the hazard early on without anticipating the operator’s decision. That is why we have developed a three-stage system. In phase one the machine gives an optical signal. In phase two, the speed of the saw blade is reduced. The operator feels the resistance very clearly. This saves us valuable time, even if it is only tenths of a second, to prepare the system for phase three and therefore for the total stop and the lowering of the unit.” The point in time at which the hazard is identified is decisive The Altendorf Group’s system is based on the early detection of a dangerous situation. Different defined situations are recognised and classified as parameters. This is technically solved by means of several cameras, the data of which are synchronised by a powerful computer. If the system detects a dangerous situation, the user is warned in two stages, as described, and in the third the danger is eliminated: There is a quick stop of the main saw blade and the quick lowering of the saw unit. And what is also important: The machine can continue working immediately after the incident. There is no damage to the machine or the saw blade – another advantage over other solutions available on the market. Due to the timely detection of a dangerous situation, lowering and braking of the saw blade are controlled and therefore do not put any additional stress on the precise guides of the saw unit. The optical system also recognises work gloves The developers of the Altendorf Group attach particular importance to the safety of the operators, they initially asked themselves: What happens if the operator wears work gloves? It quickly became clear that optical detection technology was more of an option instead of sensory solutions. The camera systems used are designed in such a way that they recognise the dangerous situation even if the user works with or without gloves. This optical solution is therefore superior to sensory systems that only react to heat and human skin. No restrictions on the materials In addition, the system is also insensitive to damp wood, as well as conductive materials and coatings. It therefore corresponds to the development goal of not restricting the actions of the machine operator. Schröder explains: “We at Altendorf know that in the more than 130 countries in which our machines are used, the overwhelming majority who operate the saw are unskilled workers. Our system protects all of those people from injury. And our trade businesses benefit economically by reducing employee and machine downtime.” When asked when the system will be ready for series production, the Altendorf Group refers to the numerous and extensive national and international acceptance procedures by employers’ liability insurance associations and authorities. Technically, the system works excellently, which was demonstrated convincingly at LIGNA. As with the solution itself, you want to be on the safe side with approval, you owe that to the operators. The patents are pending, the entire process is ongoing. Realistically, a start of sales cannot be expected before 2020.